Table of Contents

Background

Cars are part of our everyday life, whether driving by ourselves, seeing them on the roads, or riding one as a passenger. While most often ask about them including how fast they can be, what are their limits, and how much they cost, only a few wonder: “What are cars actually made out of?”

Though the query may be something that comes from a child’s curious mind, learning about the core materials utilized in the car can help us understand more about today’s automobiles. To encapsulate it in a basic way, there are hard materials, soft materials, and even shiny and transparent materials, which are built up using both art and science to produce the transport device that makes our lives easier.

In this post, let’s delve deeper into what are cars made out of, their use in making the vehicle, the composition percentage of these materials, their portion of the total cost, as well as some interesting facts you shouldn’t miss about these core materials utilized in auto manufacturing to create these innovative, sophisticated things.

How Are Cars Made?

Prior to learning about the core materials, it’s vital to have a quick understanding of the auto manufacturing process. When cars were first invented, only a few workers were needed to build a car. Today, millions and millions of automobiles fill the roads across the world, proving how advanced technology has become to allow us to produce a massive number of cars in various types, models, sizes, features, and power.

From start to finish, it usually takes around two to five years to create a new car model. It involves the raw materials gathering process, design stage, and other key steps until launch, all made to ensure that the car entices large interest from the public and that the car is built in sound condition for safe public use.

First, car manufacturers gather core materials to turn ideas into reality. As technology progresses, most car producers are now opting for more lightweight, cost-effective, and sustainable raw materials to allow their cars to stay competitive in the market and meet the rising demand for greener products.

Next in the auto-manufacturing process are design and engineering. Car manufacturers also ensure that the vehicle can fulfill both the public’s needs and wants in a car. Design and engineering specifications are drafted, and it will undergo numerous revisions to perfect the vehicle.

Small models of cars will be created in both 2D and 3D forms for testing their design for various aspects like safety, weather, aerodynamics, cost analysis, electrical functionality, fuel economy, and a lot more.

Meanwhile, the car’s interior and exterior must also be fashionable enough and have a lot of innovative features to ensure that it hits the new, attracts customers, and stays competitive against other brands.

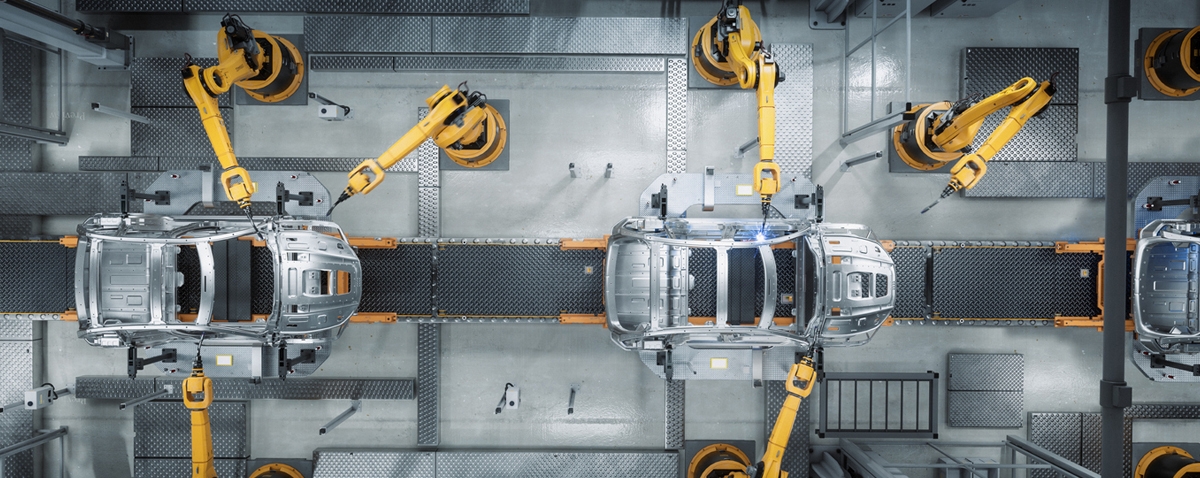

Only when the design and engineering specifications have been officially approved before the manufacturing process can start. Robots will create and stamp the sheet metal parts for the vehicle’s bodywork. It also includes doors, side frames, roofs, and hoods, which will be later incorporated onto the car’s main frame.

Once the frame and the parts are ready, the car will go into the assembly line where both humans and robots will work on it. Tasks will include attaching, assembling, welding, soldering, screwing and gluing the parts onto the car.

Once the body parts have been manufactured onto the car, the following step in the manufacturing process is detailing. It involves cleaning the car, painting, and applying formulas to protect it from scratches and corrosion. Lastly, the engine, axles, exhaust systems, transmissions, and tires are all installed into the car.

Though the car is ready to drive, it still needs to undergo safety and quality assurance checks. It will be checked for any inconsistencies or flaws in the interior and exterior design and go under a series of tests to inspect the engine, steering alignment, headlights, and brakes.

The electrical units and the car’s programming will also be tested, while crash testing will also be undertaken to see how it handles impact and to check the seat belt and airbag performance. If no further improvements or adjustments in the design are needed and the unit has been proven safe, the car is ready to be presented to the market.

Prior to the launch, the car company performs market research, devises marketing themes and strategies, and decides on the car’s pricing. Once done, the car is ready to be produced for dealers and to be sold to the public. [1] [2]

What are the Core Materials Used to Make a Car?

Various core materials are required in assembling a car. These serve as building blocks to create everything in an automobile from the smallest parts we don’t know about like the wiring and dashboard needles to the largest components like the transmission gears and the engine block. Through the years, these materials have evolved somewhat, becoming more complex, better built, and safer brought by the new technologies in the manufacturing processes. Despite such, the bulk of the stuff used to make a car largely remains the same, though have been utilized in more innovative ways.

Let’s take a look at the core materials used in car manufacturing:

1. Steel

Steel is the main core material used in a typical modern car. It is utilized in creating the major components of the automobile starting from the underlying chassis or cage that serves as the skeleton of the car and protects you in case of a crash.

Other parts like the engine block, body sheet metal, door panels, exhaust pipes, mufflers, support beams, bolts, hinges, rivets, and screws are also made of steel, for most vehicles today. It’s no surprise as steel is a cheaper, easily sourced, and easy-to-form core material that is also known for its strength and ability to hold its shape well.

Thanks to the advancement in technology through the years, there are also now different types of steel available in diverse levels of rigidity, enabling car manufacturers to use it on parts from one end of the vehicle to the other. For instance, steel now has the ability to crumple to absorb impacts and help you keep safe on the road.

Apart from being the most common material in cars for more than a century, steel is also the most important construction and engineering material in the world as it’s used nearly in everything, including home appliances and utensils, surgical tools, ships, trains, and buildings.

2. Plastic

A by-product of petroleum (oil and gas), plastics are also a prominent core material in car manufacturing and constitute a huge chunk of the total car parts. Today’s car utilizes massive amounts of plastics as they are practical, durable, lightweight, inexpensive, and can be transformed into literally anything.

A car’s dashboard, including its gauges and dials, air conditioner vents, seat belts, airbags, door handles, steering wheels, gearshift consoles, radio faceplate and are all created from different types of plastics. Even the tiny interior parts, like the oil dipstick and wire looms, use plastics. It doesn’t cease there, as the carpets and the car seats are also manufactured using materials derived from plastic strands.

Progress in plastic technology even allowed car engineers and manufacturers to use the material in components and parts that are previously made out of metal, providing how versatile plastics are and how extensively they are used in auto manufacturing.

3. Aluminum

While steel has been long used in the world of auto manufacturing, aluminum is like a newcomer. In 1970, aluminum components only made up about 2 percent of the total weight of modern vehicles, increasing to 5 percent in 1990, and 9 percent in 2009., the Across the years, the material has been increasingly used in the car industry, making up to nearly 14% of the total weight of cars today.

You’ll see aluminum in various parts, such as the wheels and hubcaps, replacing steel. It’s also used in window regulators, radio chassis, and much more. Automakers are also starting to switch to aluminum for making engines instead of the traditional iron blocks, as the former is lightweight and can disperse heat effectively.

Moreover, aluminum is also becoming more popular for car engineers who use it as the auto body to remove mass for emission and fuel economy purposes and create lighter, performance-oriented vehicles. It’s little wonder that aluminum is now evolving to be mainstream with aluminum doors, hoods, and trunk lids also now available.

4. Rubber

Most people take tires for granted. Yet, they are one of the most essential parts of the vehicle that allows us to get around and take us to our destinations. That’s where the significance of another core material in auto-manufacturing comes into the picture – rubber.

The ever-important car tires are made of rubber. That’s not simple rubber as you might think, as there are various ingredients that are used in making tires to make them safe, eco-friendly, fuel-efficient, and high performing.

For instance, the thread layers are made out of natural rubber, though synthetic rubber reinforces its strength. Metal and textile cables make up the tire’s skeleton and form its shape and make it rigid, while silica and carbon black are added for better durability. Other chemical agents are also incorporated to give tires distinct properties like improved grip and less resistance to rolling.

In addition to tires, rubber is also used in other car parts like hoses, belts, wiper blades, engine mounts, gaskets, and seals. Like plastic, rubber is incredibly durable, flexible, and cheap, allowing it to be used in a variety of ways in the automobile industry.

While rubber is vital for cars, cars are also vital for the rubber industry. Demand for natural rubber in 2019 amounted to $28.65 billion and is anticipated to rise to $33.87 billion in 2027. 65.37% of the demand in 2019 was from the automotive sector.

5. Glass

Glass is another core material that goes into many areas of a car. Obviously, it is used in creating windshields and windows, as it will be hard and unsafe to drive without properly seeing the road. Plus, it also protects you and your passengers from any elements and airborne objects that may come your way. Side-view, rear-view, and interior mirrors are also made of glass to let you see what’s around you when driving.

As technology continues to advance, glass is being utilized in devising more innovative parts on cars, such as navigation lenses and screens, making glass a truly essential component in cars. Truth to be told, glass is heavily linked to the car industry, with any drop in the business of car makers can affect the glass manufacturers and result in job losses.

6. Fiberglass

While most people deem that they’re the same, glass and fiberglass are two different materials. Fiberglass is created from extremely small thin glass fibers. It is then woven into small sheets or layers and resin painted on it to make small, lighter things. Also commonly used in auto manufacturing, you can see fiberglass in front and rear bumpers, doors, casings, roofs, hoods, V-belts, and timing belts.

Fiberglass is non-corrosive, making it an ideal choice as a replacement for steel in areas prone to corrosion. Moreover, the material is also a lightweight, durable, and fire-resistant solution to the rising demands in the automotive industry.

7. Copper

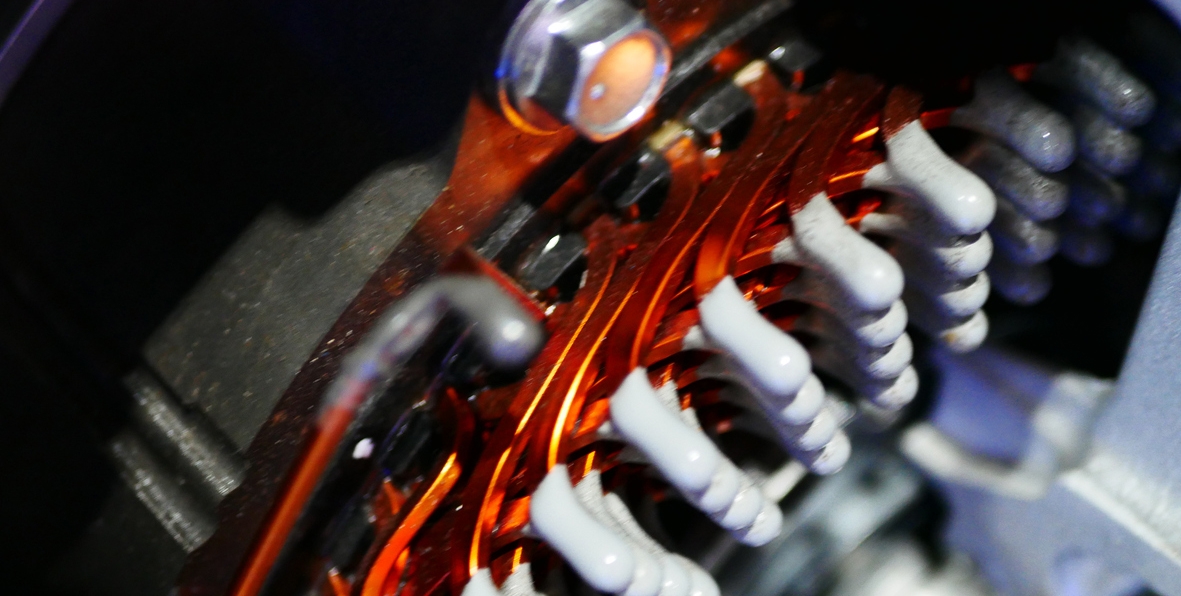

Copper is an unsung hero in the car-making industry. The miles of wires that are present in a car are virtually made out of copper cores. It boasts many properties like electrical and thermal conductivity, malleability, lubricative, corrosion resistance, creep resistance, and solderability, allowing it to be used in many other applications.

Apart from wiring, copper coils are also found in starter and alternator motors, electronic control switches and modules, brake lines, printed circuit boards, and newer versions of radiators. Charging points, radio, and safety systems also have copper wires that run through them.

According to the U.S. Geological Survey, copper ranks third as the most used industrial metal worldwide, and the reason behind its immense popularity is its amazing ability in conducting electricity, making it perfect for automobiles’ electrical wiring and electric motors. It is believed that the shiny, reddish material was the first-ever metal worked by humans, who used it in creating a wide array of tools and ornaments tens of thousands of years before.

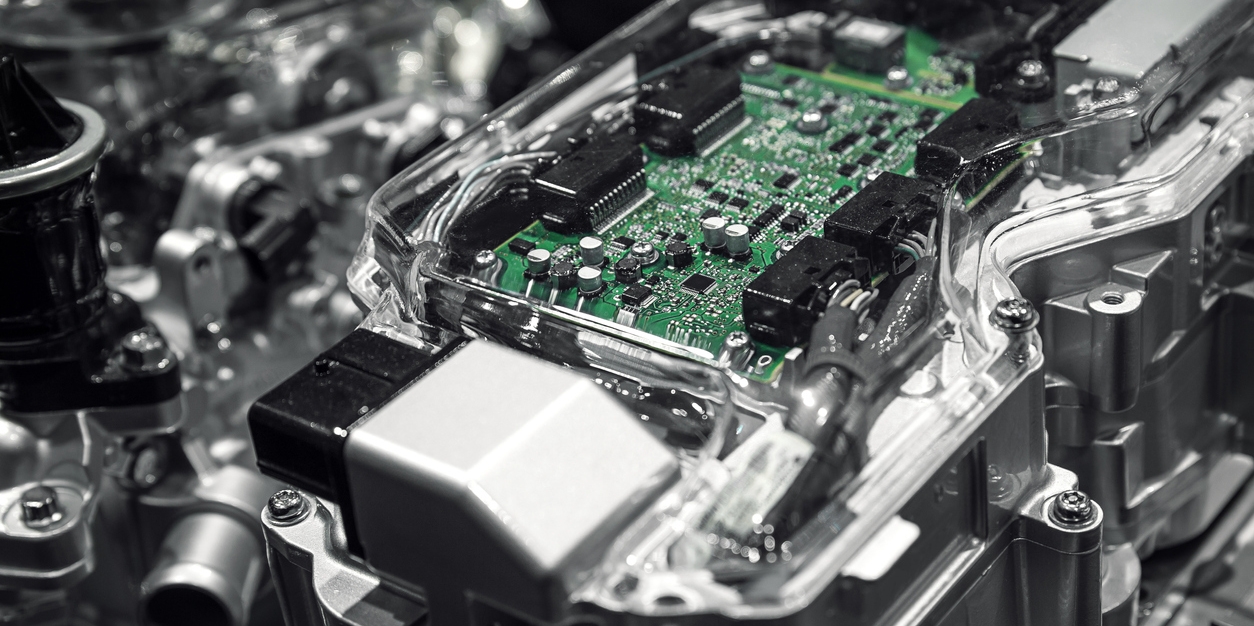

8. Gold

Yes, you can find gold in cars. However, it’s not the white or rose gold panels you can see being used in luxurious cars. Instead, gold is normally used in essential electrical system components, such as connector terminals, electrical relays of safety-critical electronic control units, and some parts of the printed circuit boards where processors are set up. Just be wary that cars aren’t worth melting as gold used in these parts only usually weighs between a gram or two.

9. Cast Iron

While aluminum is the new kid on the block, cast iron is perhaps the father of all automotive materials as it was used to create nearly everything during the older days. However, it is very heavy and is prone to rust. It was soon replaced by the lighter metals steel and aluminum, which provides various advantages in terms of corrosion susceptibility and total car weight. Today, it’s still being used in some car parts, including engine blocks and brake rotors, due to its durability and heat resistance.

10. Lead

Lead is among the most hazardous materials, which is why restrictions are imposed on the use of the materials. Gradually, it is being phased out, thanks to the advancement in lithium and lead-free solders. Today, it is being utilized mainly on car batteries, as it allows maintenance of safe temperatures even when the automobile is heating up, and on wheels due to its heaviness that helps balance the vehicle. [3] [4] [5] [6] [7] [8] [9]

Other Elements Used in Auto Manufacturing

Besides aluminum, copper, gold, and iron, many other elements are also used in manufacturing cars. To give you a glimpse, here are the other elements and their applications in automotive manufacturing:

- Bismuth: Bismuth oxychloride’s pearl hue was utilized in car paint for a relatively short period, specifically between 1998 and 2000. It replaced uranium and lead, which were both once used in car paints. Today, bismuth is still being added to create some free machining steels and other steel parts found in engines.

- Calcium: An essential mineral in steel production is calcium carbide.

- Carbon: Carbon fibers, also called graphite fiber, is a durable and lightweight material used in innumerable ways in modern cars, from frames, body panels, or ornaments.

- Chlorine: Chlorine is an essential element in creating PVC (Polyvinyl chloride), a synthetic plastic polymer used as an underbody coating and for moldings and trim parts.

- Helium: Helium serves as a mobile tracer gas used to test many auto assemblies and parts for leaks. Additionally, it is also often utilized in CAB (controlled atmosphere brazing), a manufacturing process that many automotive components undergo.

- Magnesium: Magnesium is 33% lighter than aluminum and 75% lighter than steel. It is being used in many car parts, such as rear-link arms, hoods, sub-frames, lift gates, and trunks. However, it is only for small areas to reduce some weight without throwing off the balance of the car.

- Platinum: Due to being heat- and corrosion-resistant, platinum is a vital component in a car’s catalytic converter. Today, the auto industry in the United States is the biggest consumer of platinum than any other industry.

- Titanium: Titanium is usually more expensive, which is why most car manufacturing companies prefer not to use them and opt for other cheaper metals. Those who still use titanium apply it on areas where aluminum or steel are normally used for the purpose of making the car more aesthetically appealing. [6] [10]

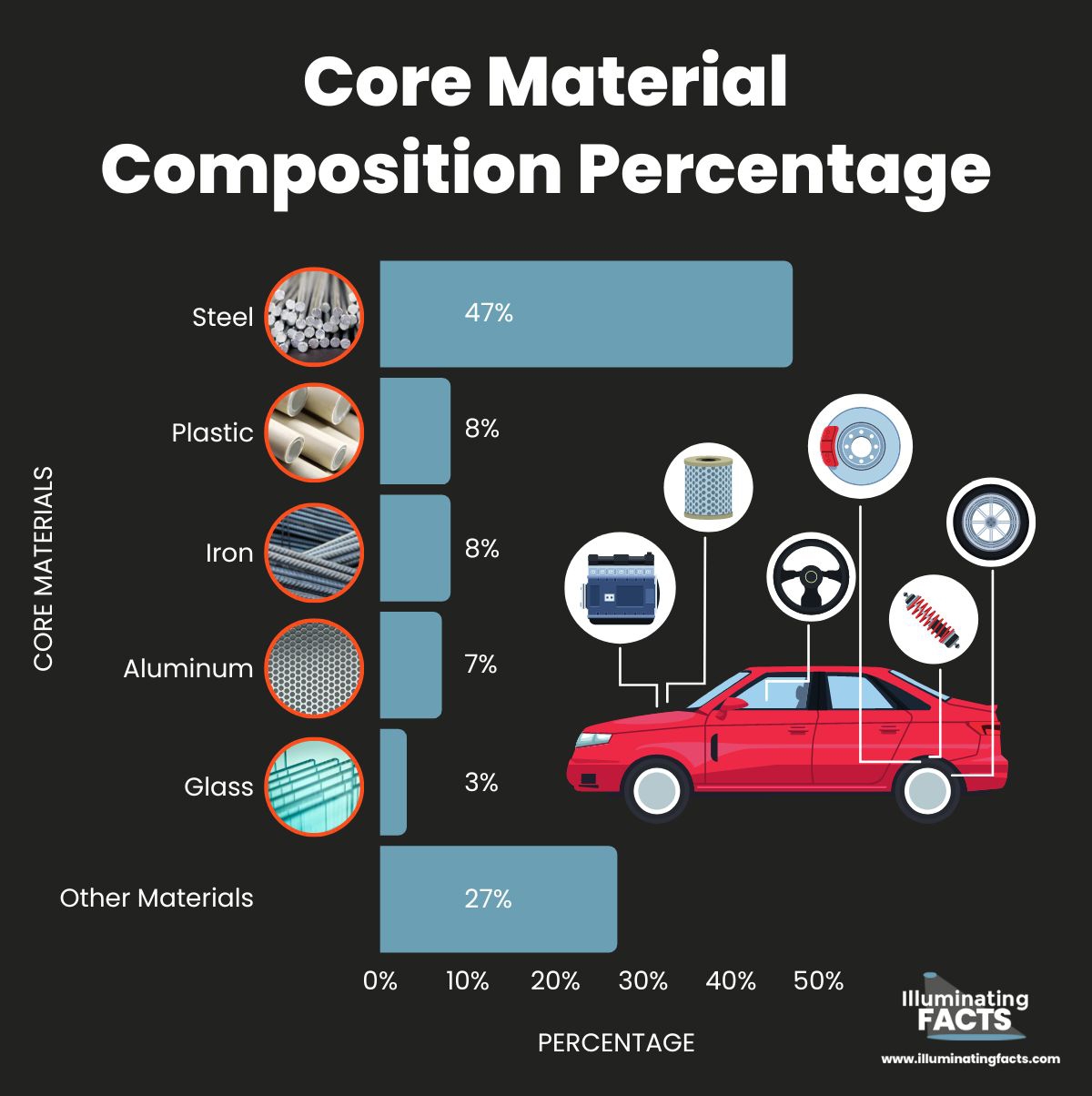

Core Materials Used in a Car Composition Percentage

On average, a car is made out of 47% steel, 8% plastic, 8% iron, 7% aluminum, and 3% glass. Other core materials account for the remaining 27% of the car parts. [11]

Core Material Composition Percentage |

|

| Core Materials | Percentage |

| Steel | 47% |

| Plastic | 8% |

| Iron | 8% |

| Aluminum | 7% |

| Glass | 3% |

| Other Materials | 27% |

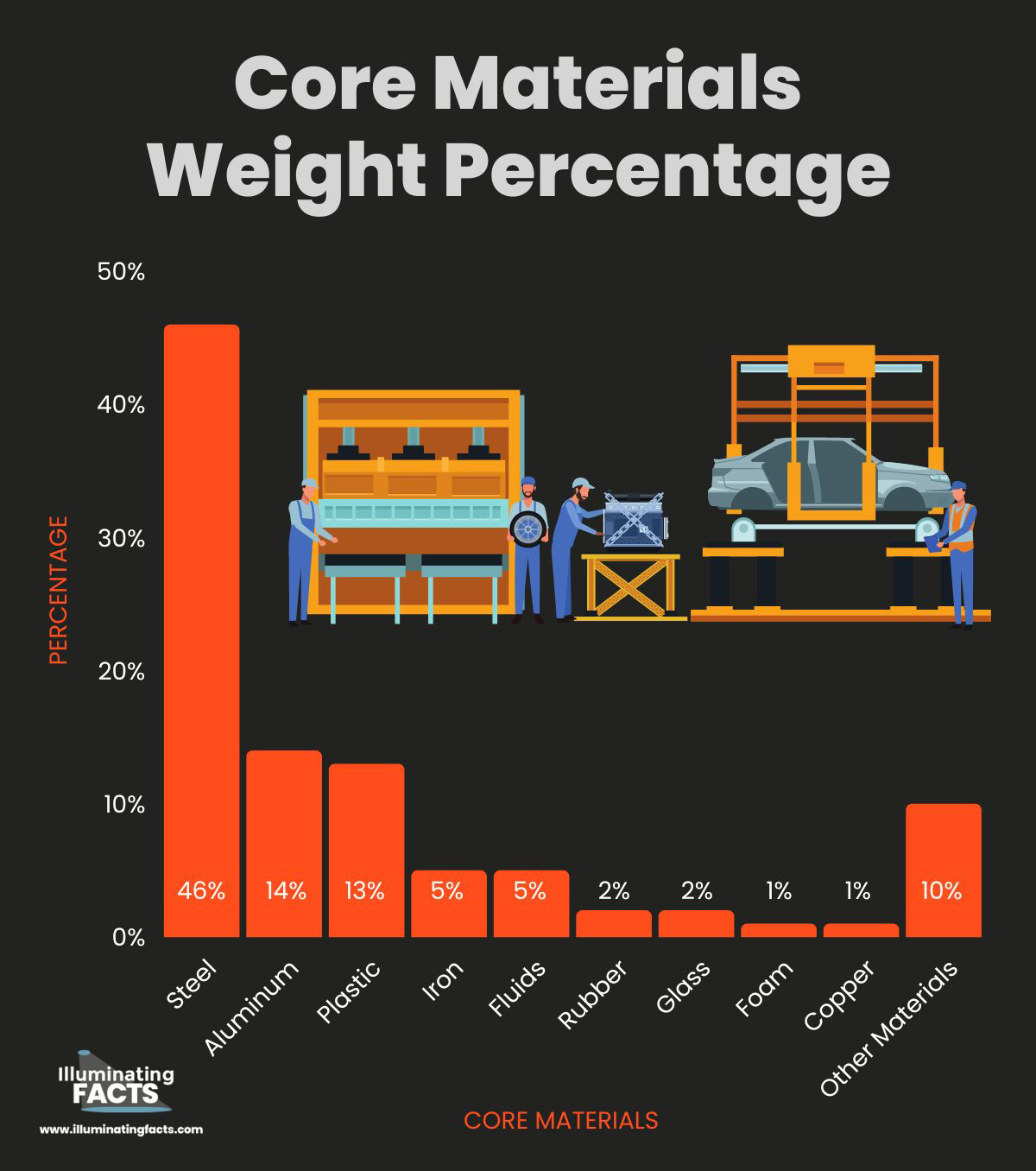

Core Materials Weight Percentage

In a Japanese study on the weight of the materials used in a vehicle, 46% of the total car weight was from steel, 14% from aluminum, 13% from plastic, 5% from iron, 5% from fluids, 2% from rubber, 2% from glass, 1% from foam, 1% from copper, and the remaining 10% was from other materials. [12]

Core Materials Weight Percentage |

|

| Core Material | Weight Percentage |

| Steel | 46% |

| Aluminum | 14% |

| Plastic | 13% |

| Iron | 5% |

| Fluids | 5% |

| Rubber | 2% |

| Glass | 2% |

| Foam | 1% |

| Copper | 1% |

| Other Materials | 10% |

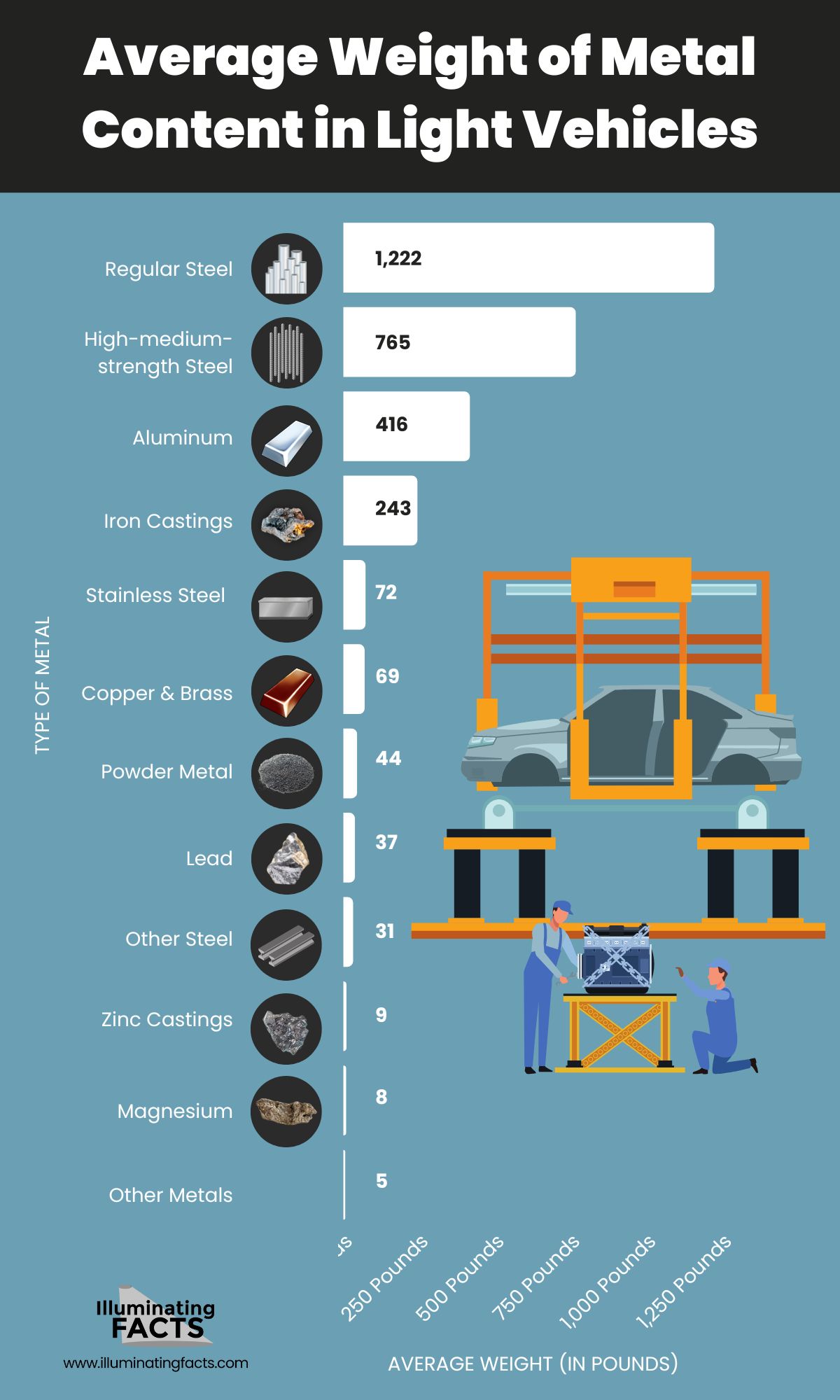

Average Weight of Metal Content in Light Vehicles

In 2017, U.S. and Canadian-built light vehicles contained an average of 1,222 pounds of regular steel, 765 pounds of high- and medium-strength steel, 416 pounds of aluminum, 243 pounds of iron castings, 72 pounds of stainless steel, 69 pounds of copper and brass, 44 pounds of powder metals, 37 pounds of lead, 31 pounds of other steel, 9 pounds of zinc castings, 8 pounds of magnesium, and 5 pounds of other metals. [13]

Average Weight of Metal Content in Light Vehicles |

|

| Type of Metal | Average Weight (in pounds) |

| Regular Steel | 1,222 |

| High- & medium-strength Steel | 765 |

| Aluminum | 416 |

| Iron Castings | 243 |

| Stainless Steel | 72 |

| Copper and Brass | 69 |

| Powder Metal | 44 |

| Lead | 37 |

| Other Steel | 31 |

| Zinc Castings | 9 |

| Magnesium | 8 |

| Other Metals | 5 |

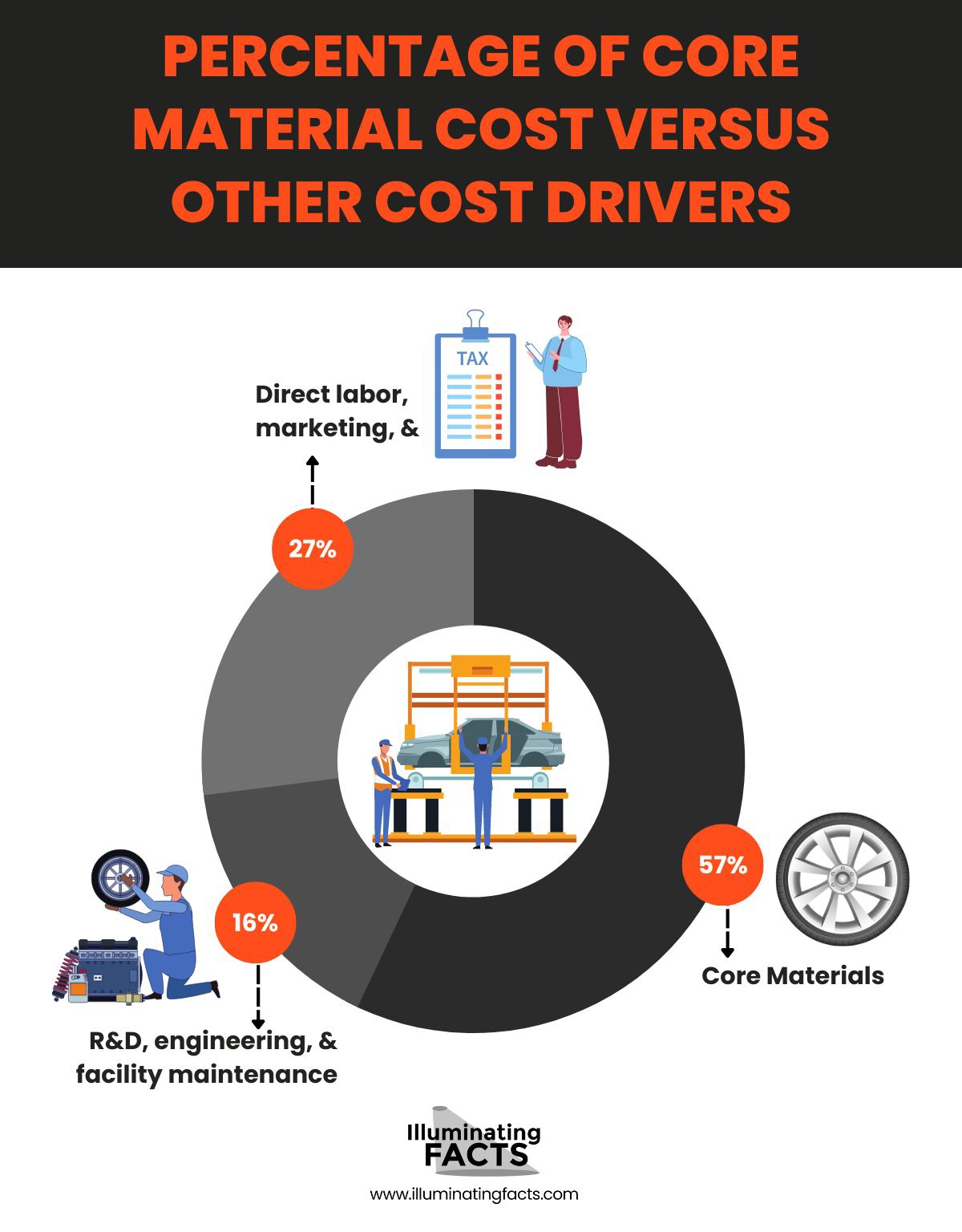

Percentage of Core Material Cost versus Other Cost Drivers

Manufacturing a car entails considerable costs, which can be categorized into two: fixed and variable costs. Fixed costs involved expenses in searching suppliers, maintaining facilities, conducting testing on prototypes, and salary of employees. As its name implies, these costs are nearly the same, regardless if a company is building an average car or a luxury model. Yet, it’s good to note that fixed costs are relatively cheaper on second-generation releases as the technology required is already available from the first model.

On the other hand, variable costs are expenses that change depending on the number of cars being made. It includes the cost of raw materials, labor, and other charges like advertising and sales tax. In general, core materials take up the biggest chunk of the cost, accounting for 57% of the manufacturing cost. 16% goes to research and development, engineering, and facilities, while the remaining 27% accounts for direct labor, marketing, and taxes. [14]

Percentage of Core Material Cost versus Other Cost Drivers |

|

| Type of Cost | Percentage of the Total Cost |

| Core Materials | 57% |

| R&D, engineering, and facility maintenance | 16% |

| Direct labor, marketing, and taxes | 27% |

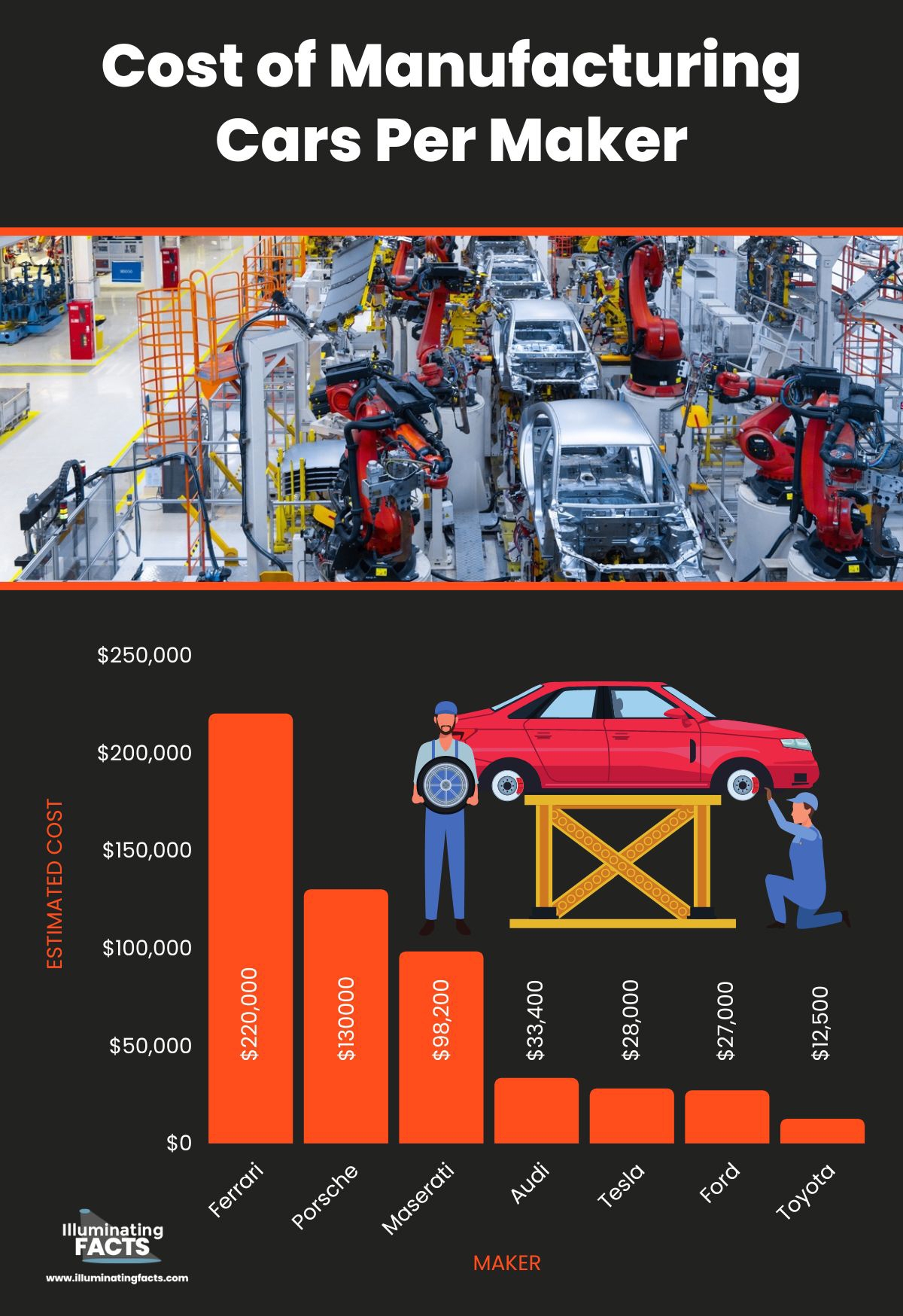

Cost of Manufacturing Cars Per Maker

Cars are indeed expensive, but prices vary per maker. Typically, the less quality core materials used and the fewer the ostentatious elements, the lower the price of the car will be. For luxury vehicles, manufacturing cost goes higher due to a lot of added features like top-notch quality leather and touchscreen dashboards.

For instance, Toyota, one of the world’s most popular car brands, has a manufacturing cost of about $12,500 for a car that sells for around $15,000. Most Japanese car manufacturers depend on large volumes of production to attain such a lower cost. Meanwhile, the estimated cost for a Ferrari is about $200,000 but can be sold for about $300,000, making them earn one of the highest revenues in the car industry. [14]

Take a look at the comparison of the cost of manufacturing a car for different automakers:

Cost of Manufacturing Cars Per Maker |

|

| Maker | Estimated Cost |

| Ferrari | $220,000 |

| Porshe | $33,000-$130000 |

| Maserati | $98,200 |

| Audi | $33,400 |

| Tesla | $28,000 |

| Ford | $27,000 |

| Toyota | $12,500 |

Interesting Facts About the Core Materials Used to Make a Car

If you want to discover more about the core material used to make a car, here are some of the most interesting facts that will blow your mind.

- Steel is roughly 1,000 stronger than pure iron.

- Aluminum is the most abundant metal in the world. As it’s readily available, it’s relatively cheaper than other, rarer metals.

- Copper is added by Exxon in their lubricants, allowing engines to run smoother and last longer.

- The 1921 Rolls Royce Silver Ghost’s body is completely made out of copper.

- Cars are the world’s most recyclable product. About 80% of an average car can be recycled.

- In the United States alone, around 12 million vehicles are recycled annually. In fact, automotive recycling ranks 16th among the largest industries in the country.

- An average car consists of 30,000 parts.

- The United States produced 1.6 million automobiles in 2021, while China produced 21 million passenger cars in the same year.

- American Iron and Steel Institute (AISI) says that a scrapped car has ample steel to create four utility poles.

- Some of the earliest documented usages of aluminum were from Ancient Greece, dating back thousands of years ago. During that time, people were dyeing their clothes with alum, which contained aluminum. Yet, it was only in the late 19th century when industrial production of the material as a metal started after the invention of the Heroult process.

- More than half of the lead produced in the world today is used for lead-acid car batteries.

- Titanium is the ninth-most abundant element found in the Earth’s crust. However, it only accounts for a measly 0.63%, making the strong and lightweight metal extremely rare and expensive compared to other metals.

- The Tesla Roadster is the first-ever commercially available car with an electric motor powered by a rotor made out of copper.

- In 1948, 55 wires of about 150 feet in length were found in an average family car. Nowadays, about 2,000 copper wires are present in luxury cars, totaling a few kilometers in length.

- Ferrari produces only about 14 cards per day, compared to Toyota’s 13,000 on a single day. Thus, making Ferrari incredibly exclusive and valuable.

- Aluminum is recyclable. It can be melted down to be reused in other applications.

- Henry Ford built a car out of soybeans in 1941.

- Cars in the early 1900s didn’t have windshields as they were considered a luxury item. Windshields caused a spike in the vehicle’s cost, which is why only the wealthiest car owners were able to afford them. It was only in 1915 when windshields were adopted as a standard feature.

- The invention of shatterproof glass was accidental. It was discovered by French chemist Edouard Benedictus in 1903 who inadvertently dropped a glass flask that once contained cellulose nitrate. The glass didn’t break, allowing him to infer that he was onto something. The invention of shatterproof glass vastly improved the safety of automobiles.

- Elvis Presley was an avid collector of cars. The “King of Rock and Roll” owned the first prototype of the Stutz Blackhawk, which contained 24K gold moldings, trim, plates, and bezels.

Conclusion

Various core materials are required to produce cars. From steel, plastics, aluminum, cast iron, rubber, copper, gold, glass, fiberglass, lead, as well as other elements. After being extracted from Earth, these materials are ingeniously transformed by automakers to create the all-important cars that we use today.

Thankfully, technology is continually advancing and more innovations on how we process core materials are being discovered to make the production even more effective, providing us with even safer and more efficient automobiles.

References

- How are cars made? Wonderopolis. (n.d.). Retrieved September 13, 2022, from https://www.wonderopolis.org/wonder/how-are-cars-made

- User, G. (2022, August 15). Step-by-step process of manufacturing a car – NRTC automation. Industrial Automation Services | NRTC Automation. Retrieved September 13, 2022, from https://nrtcautomation.com/blog/step-by-step-process-of-manufacturing-a-car

- George, P. E. (2009, October 5). Top 5 materials used in auto manufacturing. HowStuffWorks. Retrieved September 13, 2022, from https://auto.howstuffworks.com/under-the-hood/auto-manufacturing/5-materials-used-in-auto-manufacturing.htm

- Unrau, J. (n.d.). What materials are used in car manufacturing. AutoGuru. Retrieved September 13, 2022, from https://www.autoguru.com.au/car-advice/articles/what-materials-are-used-in-car-manufacturing

- Webteam. (2020, September 8). What are cars made of? 10 of the top materials used in auto manufacturing. Mayco International – Automotive tier 1 supplier. Retrieved September 13, 2022, from https://maycointernational.com/blog/what-are-cars-made-of/

- Different materials used in the making of our cars!: Team-bhp. Team. (n.d.). Retrieved September 14, 2022, from https://www.team-bhp.com/news/different-materials-used-making-our-cars

- What are cars made out of? J.D. Power. (n.d.). Retrieved September 14, 2022, from https://www.jdpower.com/cars/shopping-guides/what-are-cars-made-out-of

- Maverick, J. B. (2022, July 13). What raw materials do auto manufacturers use? Investopedia. Retrieved September 14, 2022, from https://www.investopedia.com/ask/answers/062315/what-types-raw-materials-would-be-used-auto-manufacturer.asp

- Cast Iron Automotive Applications. Metal Casting Institute. (2020, April 21). Retrieved September 14, 2022, from https://metalcastinginstitute.com/cast-iron-automotive-applications/

- Writers, B. B. S. B. S. (2019, October 23). What’s in a car, truck or SUV? Periodic Table of vehicle elements can show you. BodyShop Business. Retrieved September 14, 2022, from https://www.bodyshopbusiness.com/whats-car-truck-suv-periodic-table-vehicle-elements-can-show/

- Yahoo! (n.d.). Raw materials – the biggest cost driver in the auto industry. Yahoo! Finance. Retrieved September 15, 2022, from https://finance.yahoo.com/news/raw-materials-biggest-cost-driver-180628123.html

- Materials used in terms of weight percentage of the studied vehicle … (n.d.). Retrieved September 15, 2022, from https://researchgate.net/figure/Materials-used-in-terms-of-weight-percentage-of-the-studied-vehicle_fig2_326200226

- Published by Statista Research Department, & 12, A. (2022, April 12). U.S. & canada – vehicle metal content weight by type 2017. Statista. Retrieved September 15, 2022, from https://www.statista.com/statistics/882580/us-and-canadian-built-vehicles-average-metal-content-weight-by-type/

- Cech, B. (2022, June 3). How much does it actually cost to manufacture a car? LLCTLC. Retrieved September 15, 2022, from https://www.llctlc.com/post/how-much-does-it-cost-to-manufacture-car

- Staff, E., By, & Staff, E. (2022, July 24). 102 interesting facts about cars that you should know – page 2 of 2. The Fact File. Retrieved September 16, 2022, from https://thefactfile.org/car-facts/2/

- 7 facts about steel you need to know: Blog posts. OneMonroe. (2019, October 17). Retrieved September 16, 2022, from https://monroeengineering.com/blog/7-facts-about-steel-you-need-to-know/

- Hanses, M. (2021, September 10). Craziest Fun Facts About Cars. Wrench. Retrieved September 16, 2022, from https://wrench.com/blog/craziest-fun-facts-about-cars/

- 7 fast facts about aluminum: Blog posts. OneMonroe. (2019, October 18). Retrieved September 16, 2022, from https://monroeengineering.com/blog/7-fast-facts-about-aluminum/

- Anne Marie Helmenstine, P. D. (2018, September 20). 10 lead element facts. ThoughtCo. Retrieved September 16, 2022, from https://www.thoughtco.com/lead-element-facts-608167

- Glass, Q.-S. A. (2019, March 12). 6 fun auto glass facts – quick-set Auto Glass. Quick. Retrieved September 16, 2022, from https://quicksetautoglass.com/6-fun-auto-glass-facts/

- 6 surprising facts about titanium. OneMonroe. (2022, April 14). Retrieved September 16, 2022, from https://monroeengineering.com/blog/6-surprising-facts-about-titanium/

- McCamish, B. (2021, May 4). 50 interesting facts about gold. InvestingAnswers. Retrieved September 16, 2022, from https://investinganswers.com/articles/surprising-facts-about-gold

- Placek, M. (2022, April 22). U.S. passenger car production. Statista. Retrieved September 16, 2022, from https://www.statista.com/statistics/184171/us-passenger-car-production-since-1994/